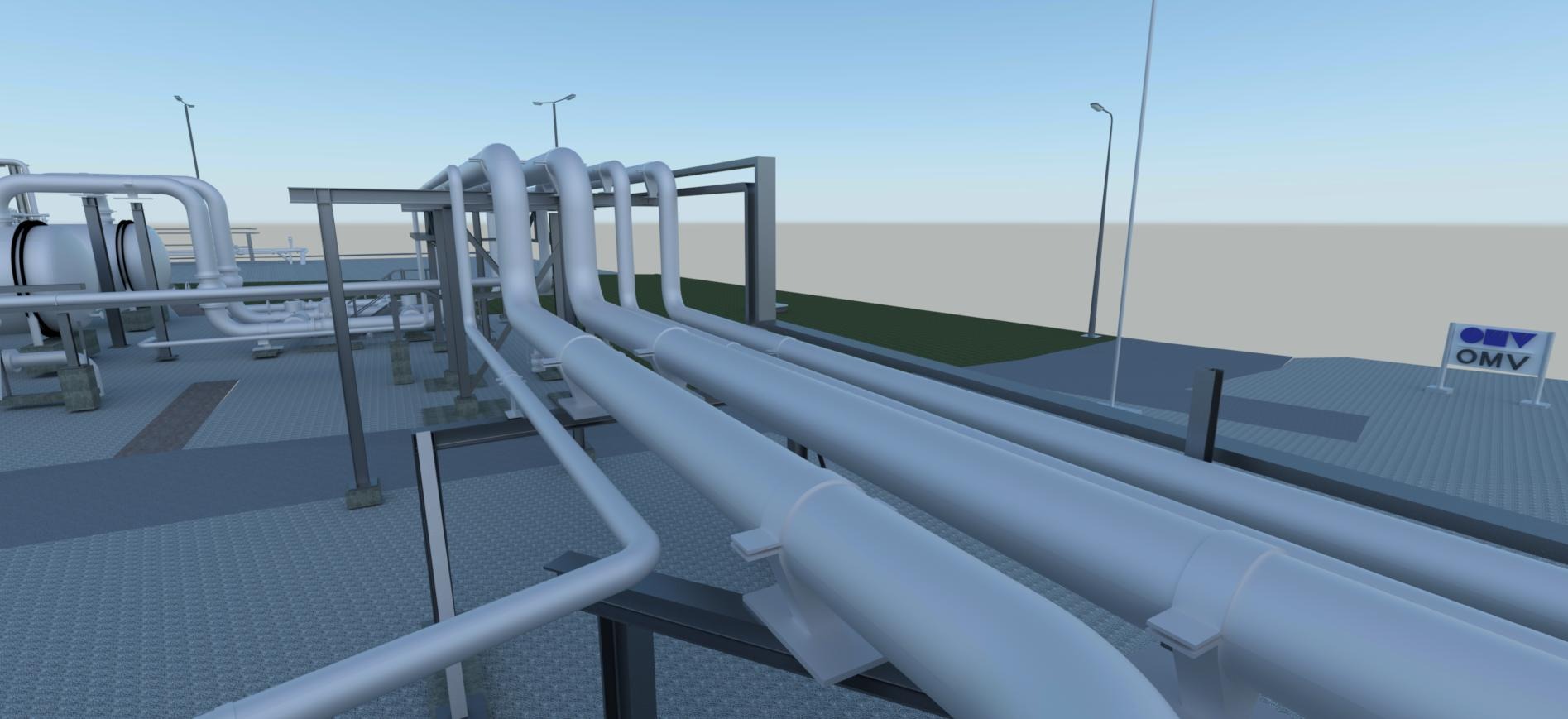

Piping & Plant Layout Engineering

Our piping and plant layout engineering services are designed to ensure the efficient and safe transportation of fluids and gases within your facilities. By combining advanced design techniques with industry best practices, we create layouts that optimize space utilization and facilitate smooth operational workflows. Our approach begins with a thorough understanding of your specific requirements, allowing us to develop tailored solutions that address both functional and regulatory demands.

A critical component of our piping engineering is stress analysis, which evaluates the structural integrity of piping systems under various operational conditions. This ensures that our designs can withstand thermal expansion, pressure fluctuations, and other forces that may affect performance. By employing advanced simulation tools, we identify potential issues early in the design process, minimizing risks and enhancing safety.

Our team of experienced engineers collaborates closely with clients throughout the project lifecycle, from conceptual design to final installation, ensuring seamless integration with other engineering disciplines. We prioritize not only the technical aspects of our designs but also their impact on overall plant efficiency and safety.

Main Deliverables for Piping & Plant Layout Engineering:

- Comprehensive piping system design and layout plans

- Detailed isometric drawings for fabrication and installation

- Stress analysis reports and compliance documentation

- Material selection and specifications based on service conditions

- Support and anchorage design for optimal system stability

- P&ID (Piping and Instrumentation Diagrams) creation and updates

- Integration of safety and regulatory requirements into designs

Piping Stress Analysis

The most significant task in Piping Design is Piping Stress Analysis. Once the pipes have been routed following the design criteria, they must be checked using piping stress analysis to guarantee that they will function properly during their design life. GIZIL has extensive project expertise in performing stress analysis services and piping flexibility studies for pipe systems. We do comprehensive pipe stress study, assessment, and validation of structural and operational integrity process piping system. Code and standards used for process piping stress analysis are ASME B31.3, ASME B31.1, API 610, API 676, API 617, ASME Sec VIII, ASME B 31.4/ASME B 31.8, and ISO 14692. We can perform pipe support selection, support standards development, support drawings, and surge analysis.