Revolutionizing Process Industries with Digital Twin Technology: Optimize Operations, Enhance Knowledge Transfer, and Drive Sustainability for a Resilient Future

Our advanced digital twin technology addresses key challenges in the process industries, including chemical, oil, gas, and tank terminals. As companies navigate an increasingly complex landscape, our solution specifically targets several critical pain points that affect operational efficiency and overall performance.

Key Challenges in the Industry

Time Wastage: Many organizations face inefficiencies that lead to significant time loss in operations. Traditional methods of monitoring and managing processes can be slow and cumbersome, resulting in delayed decision-making and increased operational costs. Our digital twin technology optimizes workflows by providing real-time data and insights, allowing teams to identify bottlenecks and streamline processes. This leads to faster response times, reduced downtime, and substantial cost savings.

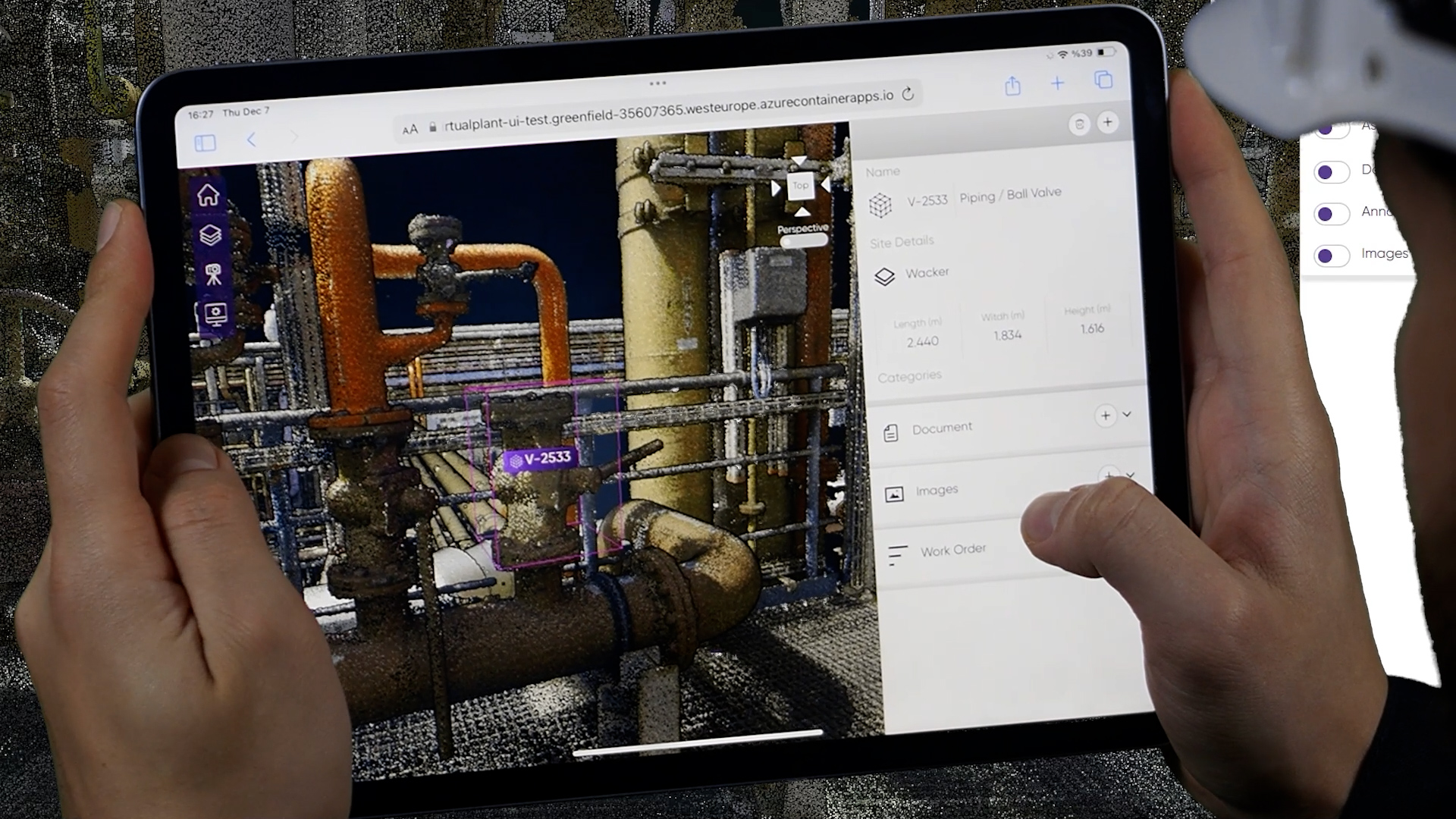

Knowledge Transfer: With a growing generational gap in the workforce, transferring knowledge from experienced employees to Gen Z workers is essential. The complexity of processes and the vast amount of data can be overwhelming for new employees. Our platform visualizes complex processes and incorporates interactive training modules that break down information into digestible formats. By making data accessible and understandable, we facilitate effective learning, ensuring that valuable knowledge is retained within the organization and passed down to future generations.

Rising Energy Costs: Geopolitical tensions and global market fluctuations have led to increased energy prices, presenting a significant challenge for many industries. Organizations must find ways to manage these costs while maintaining efficiency. Our solution identifies inefficiencies in energy usage and provides actionable insights for optimization. By analyzing consumption patterns and offering recommendations, we help companies mitigate the impact of rising energy prices and reduce their overall energy footprint.

Environmental, Social, and Governance (ESG) Compliance: As sustainability becomes a priority, organizations must meet ESG criteria to remain competitive and compliant. Our technology equips companies with the tools needed to monitor their environmental impact, track emissions, and implement strategies for reduction. By providing data-driven insights, we enable businesses to align their operations with sustainability goals, ensuring compliance and supporting long-term viability in an increasingly eco-conscious market.

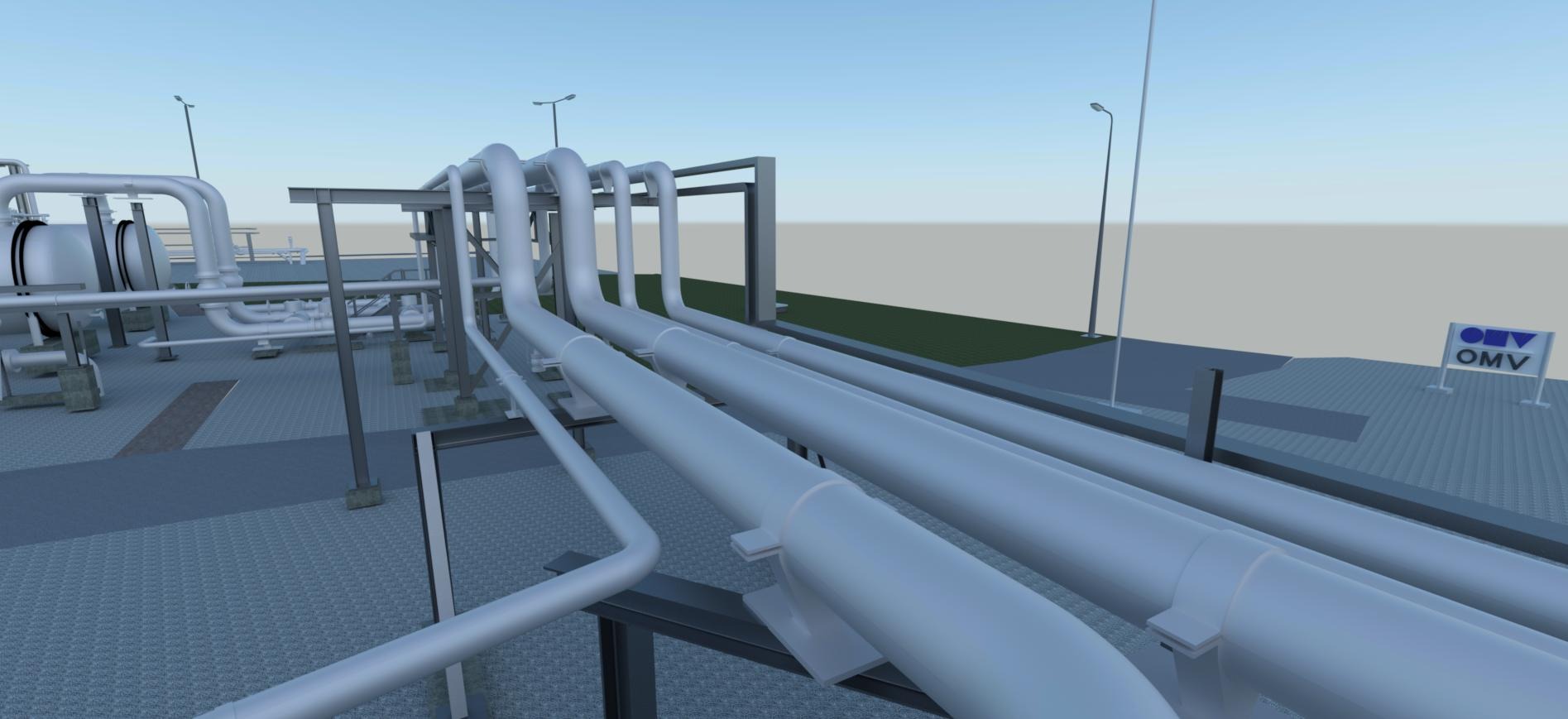

Our Full Scope Services and Virtual Plant Software

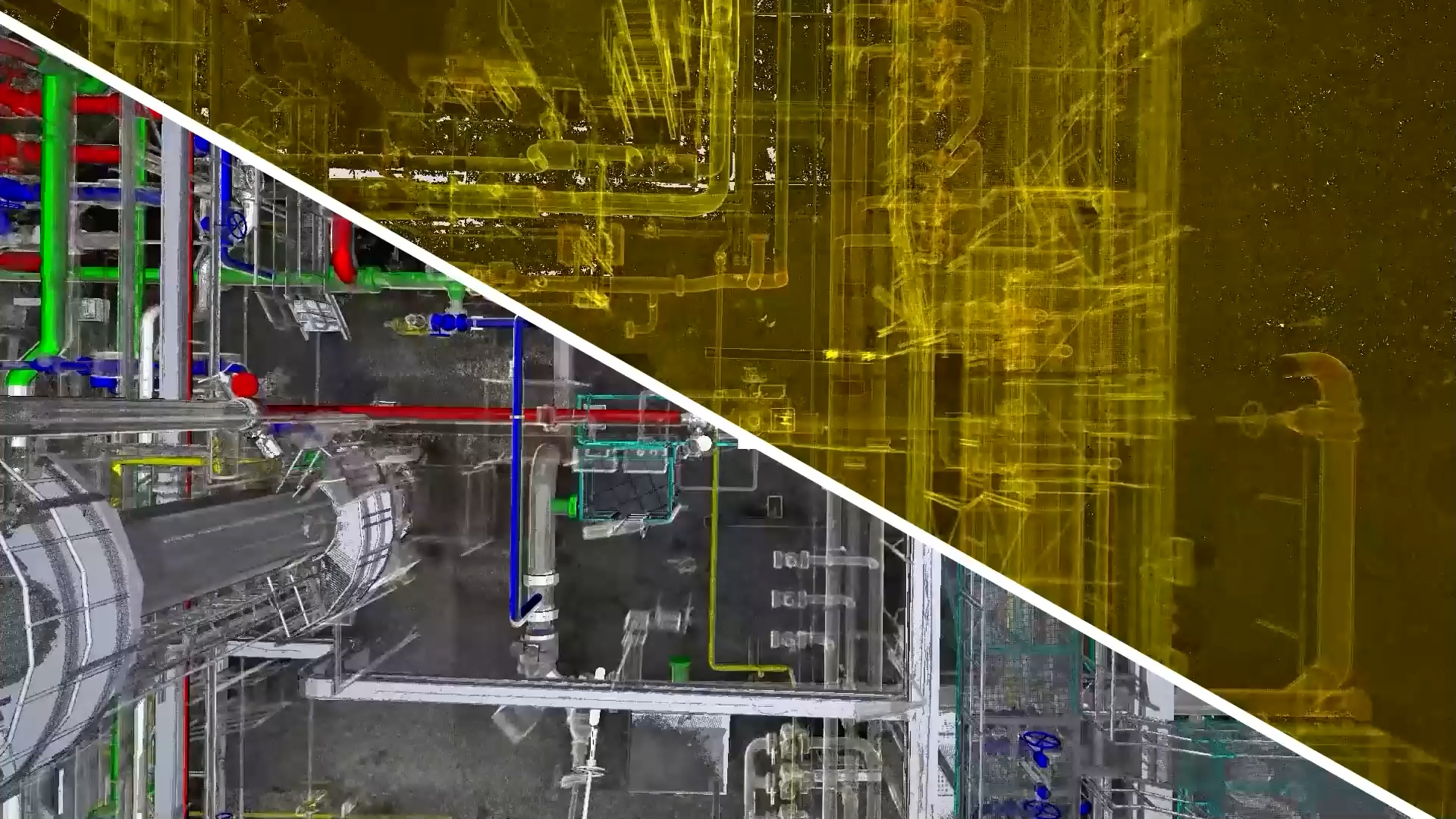

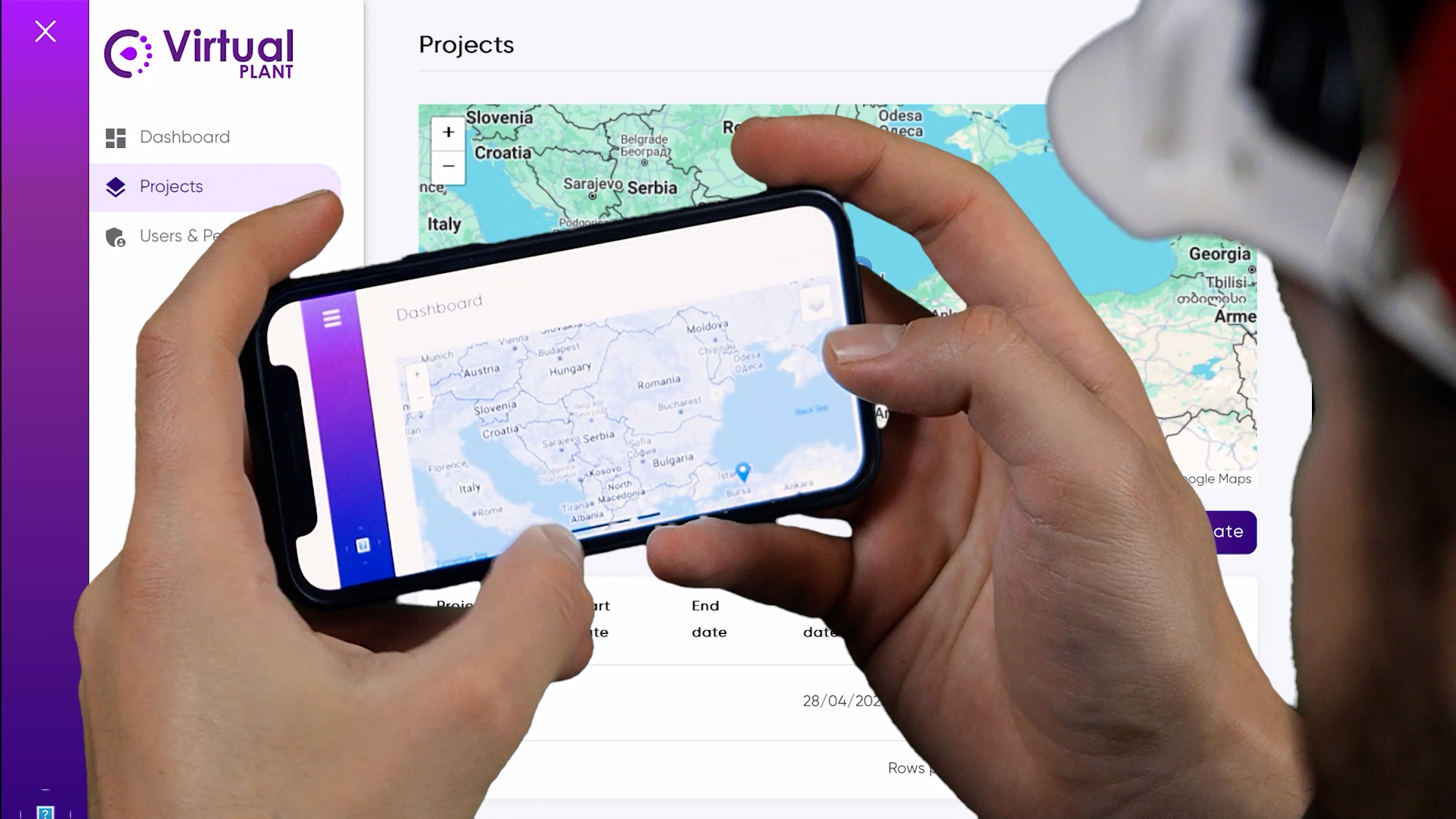

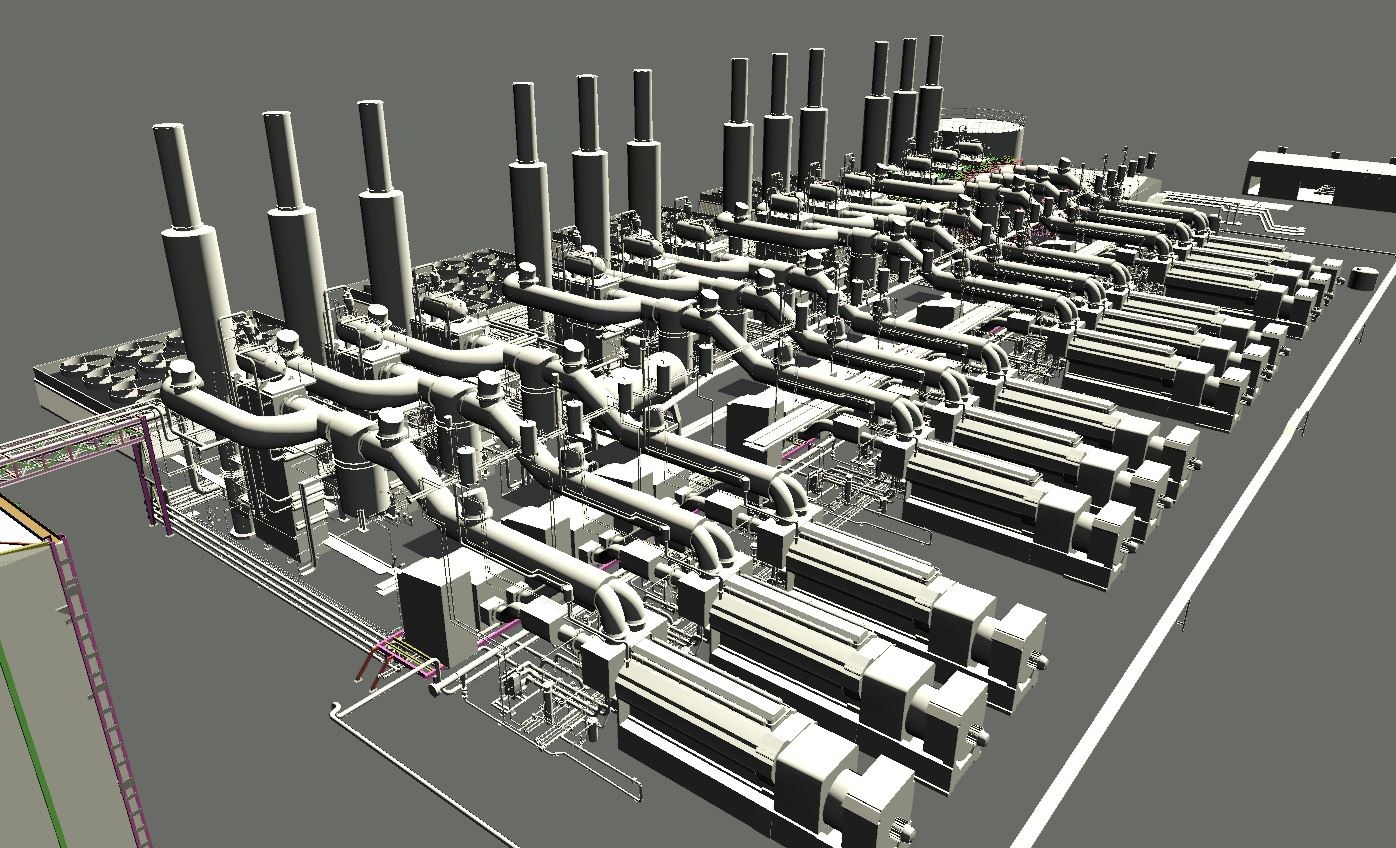

We offer a comprehensive range of services designed to enhance your operations, with our cutting-edge Virtual Plant software at the forefront. This software creates a detailed digital replica of terminal operations, centralizing data access and facilitating collaboration across teams. By integrating all relevant information into a single platform, we enable real-time monitoring and management, which improves decision-making and operational performance.

Our Virtual Plant solution includes features such as:

Real-time Monitoring: Access to live data enables teams to monitor operations continuously, allowing for quick adjustments and proactive issue resolution.

Data Visualization: Intuitive dashboards and visualizations make it easy to interpret complex data, helping teams identify trends and make informed decisions.

Simulation and Modeling: Our platform allows for the simulation of various scenarios, enabling organizations to test strategies and optimize processes before implementation.

Collaboration Tools: Integrated communication features facilitate teamwork, ensuring that all stakeholders are aligned and informed.

Linking to the Industrial Metaverse and Industry 4.0

Our approach aligns seamlessly with the principles of the Industrial Metaverse and Industry 4.0, where digital technologies converge to create smarter, more connected operations. By integrating IoT, AI, and data analytics into our digital twin framework, we transform traditional processes into dynamic ecosystems that promote innovation, agility, and resilience.

The Industrial Metaverse represents a new era of industrial operations, where virtual environments enable organizations to simulate, visualize, and optimize their processes in real time. By embracing these advancements, businesses can improve collaboration, enhance training, and make data-driven decisions that drive growth and efficiency.

In summary, our digital twin technology not only addresses key industry challenges but also enhances operational performance, promotes sustainability, and delivers significant value to our clients. By embracing the Digital Plant and Industrial Metaverse, organizations can position themselves for future success in an evolving landscape, ensuring they remain competitive and resilient in the face of new challenges. Our commitment to innovation and excellence will empower your organization to thrive in this new industrial era.