Our client is a global leader in the chemical industry, renowned for their commitment to innovation and sustainability. With a strong emphasis on operational excellence, they continuously seek to enhance their facilities and processes to meet evolving market demands. This project highlights their dedication to maintaining high standards in asset management and facility optimization through advanced digital technologies.

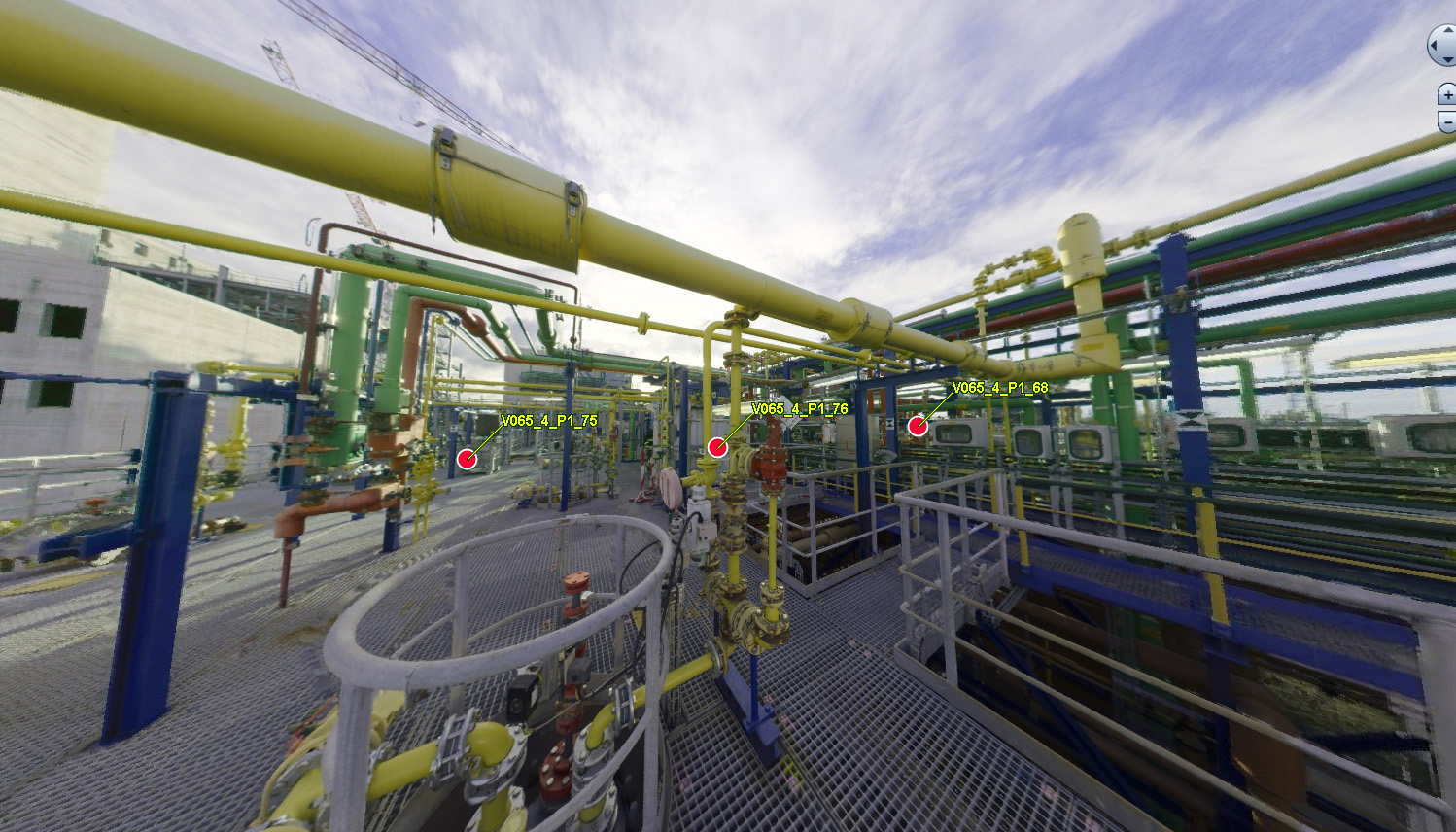

The primary objective of this project was to undertake the digital plant projects for the tankfarms V065 and V068 at the SCF plant. This involved comprehensive 3D laser scanning and the creation of 3D smart models using AVEVA software. The existing models of both tankfarms were a mix of modeled elements (pipes, equipment, civil structures) and unmodeled components. The project aimed to accurately remodel the elements that had not yet been captured and adjust existing elements to align with the point cloud data, ensuring compliance with our modeling specifications.

The expected results included a fully updated and accurate digital representation of the tank farms, facilitating improved asset management, maintenance planning, and operational efficiency. By ensuring that all components are accurately modeled and compliant with tolerances, the project would enhance decision-making processes and optimize facility operations.

Gizil played a critical role in the successful execution of this project, delivering the following contributions and engineering outputs:

3D Laser Scanning: Conducted comprehensive laser scanning of the tank farms to capture precise point cloud data, ensuring an accurate representation of the existing site conditions.

3D Smart Modeling: Developed detailed 3D smart models using AVEVA software, incorporating both existing and newly modeled elements for a complete digital representation of the tank farms.

Remodeling Uncaptured Elements: Identified and accurately modeled elements that were previously unmodeled, ensuring that all components of the tank farms are documented.

Adjustment to Point Cloud Data: Adjusted existing modeled elements to align with the point cloud data, ensuring compliance with our modeling specifications and tolerances.

Data Integration: Integrated the updated models into the existing digital plant framework, facilitating seamless access to critical information for operational teams.

Documentation and Reporting: Provided comprehensive documentation of the modeling process, including specifications, methodologies, and final outputs, ensuring transparency and accountability.

Why Gizil?

Gizil distinguishes itself in the industry with our unique combination of advanced technologies and deep sector expertise. Our commitment to quality, accuracy, and collaboration allows us to tailor our services to meet the specific needs of each client.

By choosing Gizil, clients gain access to a wealth of experience in managing complex digital projects, ensuring that their facilities are equipped with the most accurate and up-to-date information. Our dedication to innovation and operational excellence positions us as a trusted partner for organizations looking to enhance their asset management and optimize their facilities.