Our client is a renowned global leader in specialty chemicals, recognized for their commitment to sustainability and innovation in their operations. With a strong presence in various markets, they continuously invest in technology and infrastructure to enhance their production capabilities and improve efficiency. This project reflects their dedication to expanding their operations while maintaining high standards of quality and safety.

Project Objective and Expected Results

The primary objective of this project was to execute basic and detailed engineering for the expansion of adsorber capacity. This initiative aimed to increase production capabilities and optimize operational efficiency by ensuring that all engineering processes were meticulously planned and executed. The expected results included a comprehensive set of engineering drawings and documentation that would support the installation and commissioning of the new adsorber system.

By developing a full suite of engineering deliverables, the project sought to facilitate seamless integration with existing systems and processes, ensuring that the new capacity could be brought online with minimal disruption. The deliverables would enable effective communication among stakeholders and support compliance with industry standards.

Gizil's Contribution and Main Deliverables

Gizil played a crucial role in the successful execution of this project, delivering the following comprehensive contributions and engineering outputs:

Site Plans: Developed detailed site plans to facilitate the layout and integration of the new adsorber capacity within the existing facility.

Installation Plans: Created installation plans that outline the procedures for equipment installation, ensuring safety and efficiency.

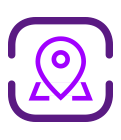

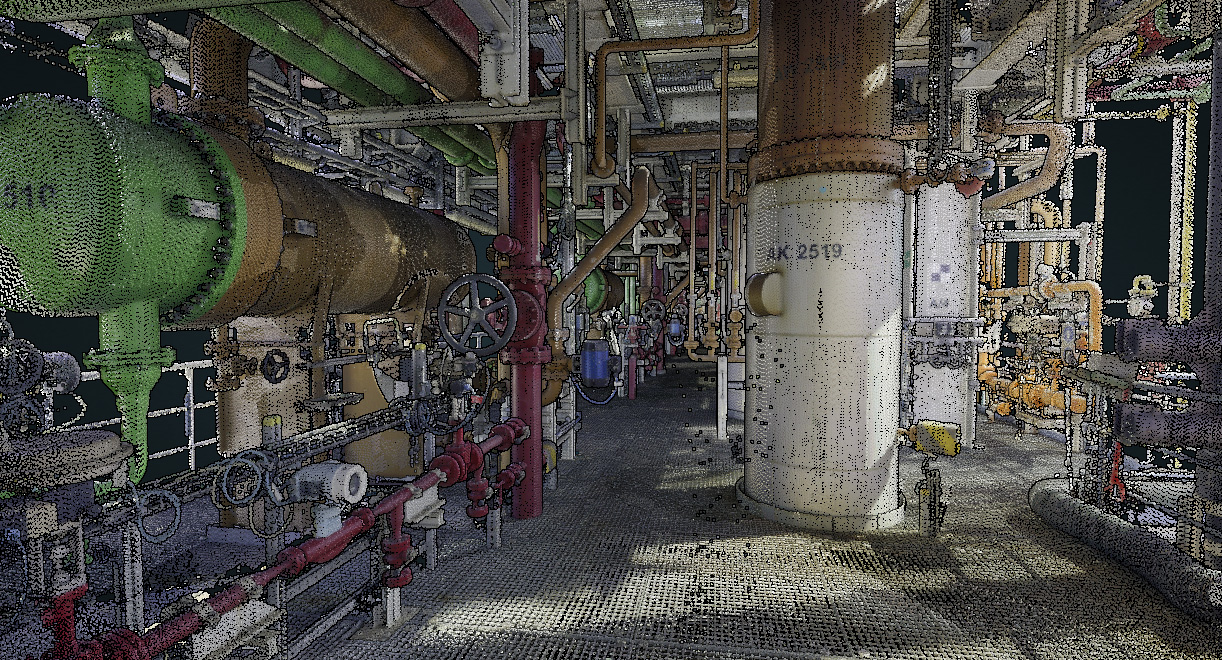

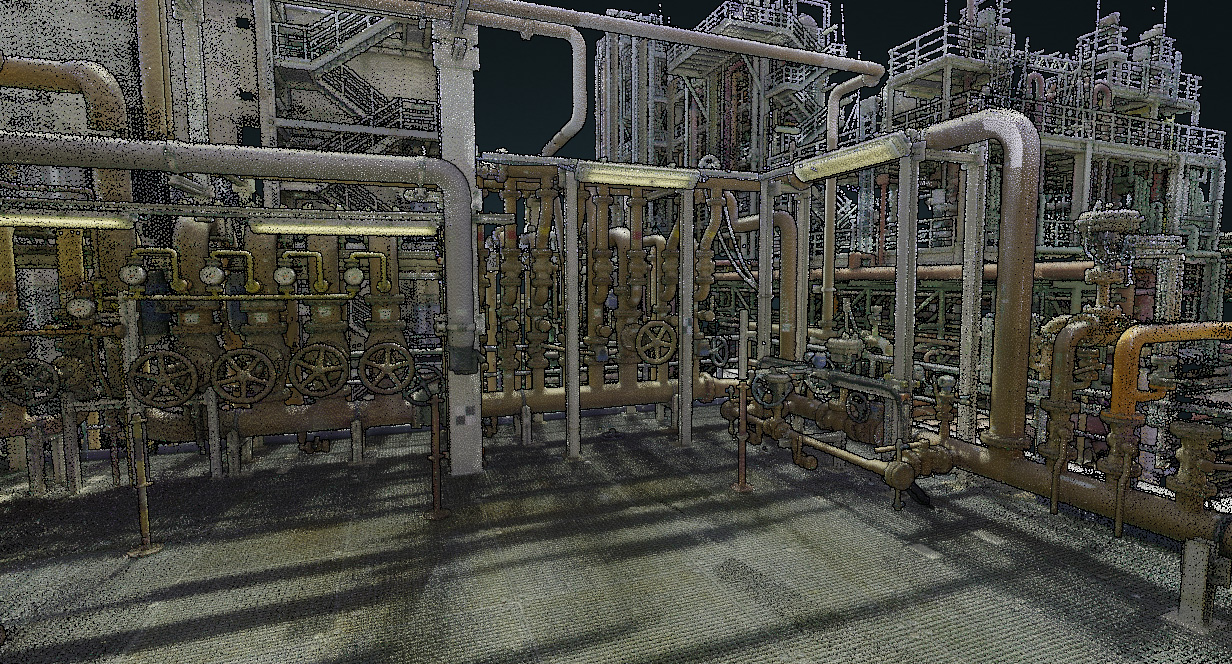

Pipe Plans and Sections: Generated precise pipe plans and sections derived from the 3D model, ensuring accurate representation of piping configurations.

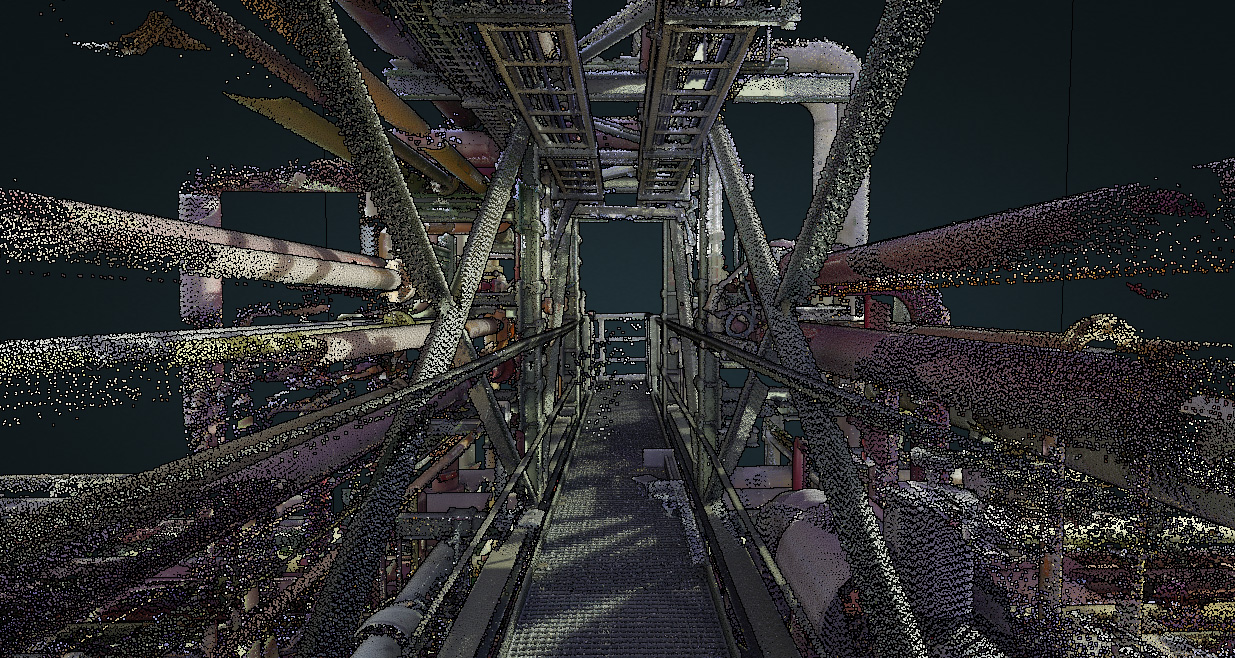

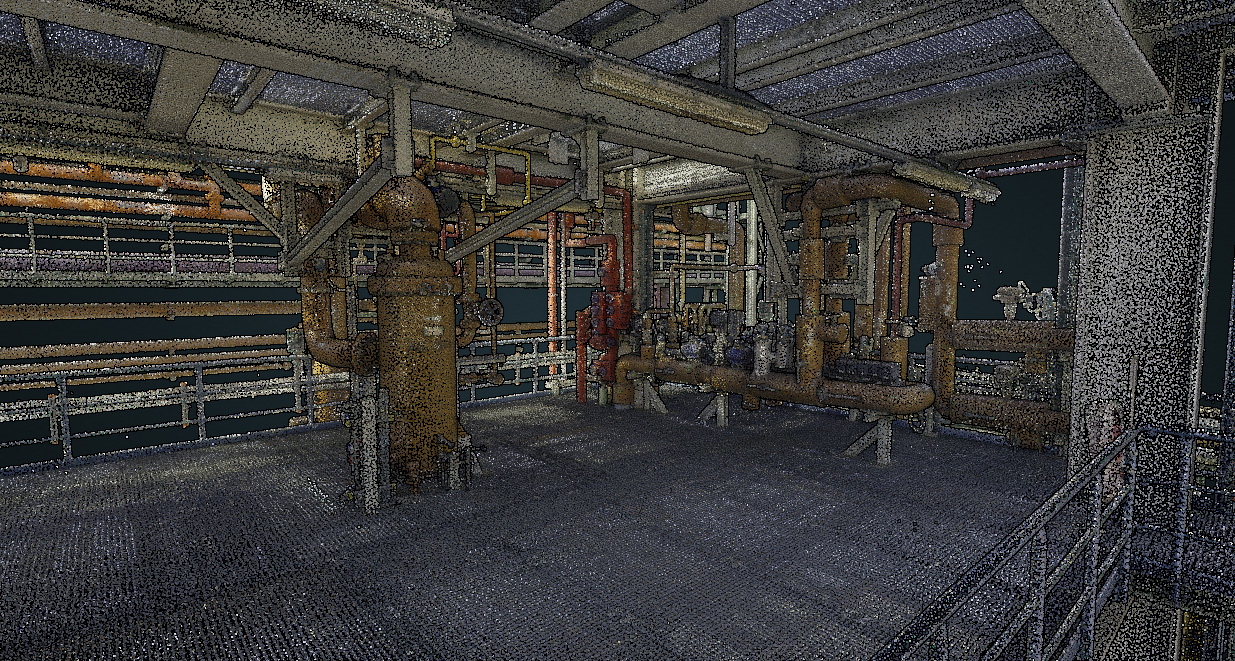

3D Model: Utilized AVEVA 3D modeling software to develop a detailed 3D model of the expanded adsorber capacity, enhancing visualization and collaboration.

Process Flow Diagrams (PFDs): Created process flow diagrams to illustrate the flow of materials and processes involved in the adsorber operation.

Piping and Instrumentation (R+I) Schemes: Designed comprehensive R+I scheme to represent the relationships between piping and instrumentation components.

Apparatus Lists: Compiled detailed lists of all apparatus required for the expanded capacity, ensuring comprehensive documentation.

Technical Inquiry Specifications: Developed specifications to guide technical inquiries related to equipment and materials.

Pipe Classes and Project Pipe Classes: Established pipe classes to standardize piping components for the project.

Piping Lists: Created exhaustive piping lists detailing the specifications for each pipe used in the system.

Piping and Fittings Specifications: Developed specifications for all piping and fittings to ensure compliance with industry standards.

Media and Pipe Class List: Compiled a list of media types and associated pipe classes for accurate material selection.

Standard and Special Component Specifications: Documented specifications for both standard and special components required for the installation.

Isometric Drawings: Produced isometric drawings to provide a three-dimensional view of the piping layout for construction reference.

Pipeline Calculations: Conducted necessary calculations, including stress analysis and other engineering assessments, to ensure the integrity and safety of the pipeline design.

Additional Calculations: Completed any other required calculations for apparatus, pipelines, and mass/energy balances created during order processing.

Mount Point List: Compiled a comprehensive list of mount points for all equipment and piping to ensure proper installation.

Why Gizil?

Gizil stands out as a trusted partner in engineering projects, offering a unique combination of advanced technology, industry expertise, and a commitment to quality. Our approach emphasizes collaboration and customization, allowing us to tailor our services to meet the specific needs of each client.

By choosing Gizil, clients benefit from our extensive experience in handling complex engineering challenges, ensuring that projects are executed efficiently and effectively. Our dedication to precision and safety, coupled with our comprehensive suite of engineering deliverables, positions us as a leader in supporting expansion projects in the chemical industry and beyond.